Water Mining

funding: EU Funded H2020: H2020-SC5-2018-2019-2020

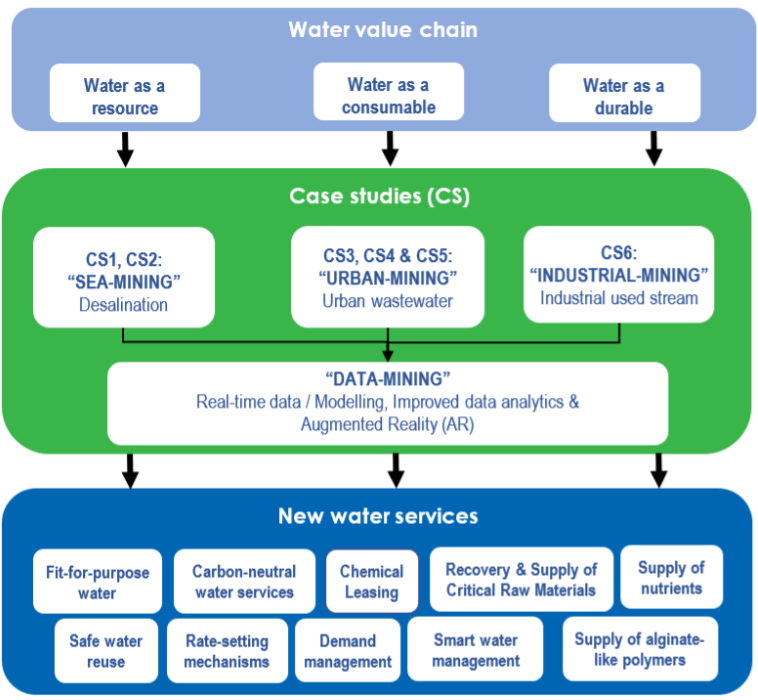

status: KO

This project aims to provide for real-world implementations of Water Framework Directive and the Circular Economy packages by showcasing and validating innovative next generation water resource solutions at pre-commercial demonstration scale. These solutions combine WATER management services with the recovery of value added renewable resources extracted/MINED from alternative water resources ("WATER-MINING"). The project will integrate selected innovative technologies that have reached proof of concept levels under previous EU projects. The value-added endproducts (water, platform chemicals, energy, nutrients, minerals) are expected to provide regional resource supplies to fuel economic developments within a growing demand for resource security. Different layouts for urban wastewater treatment and seawater desalination are proposed, to demonstrate the wider practical potential to replicate the philosophy of approach in widening circles of water and resource management schemes. Innovative service-based business models (such as chemical leasing) will be introduced to stimulate progressive forms of collaboration between public and private actors and access to private investments, as well as policy measures to make the proposed water solutions relevant and accessible for rolling out commercial projects in the future. The goal is to enable costs for the recovery of the resources to become distributed across the whole value chain in a fair way, promoting business incentives for investments from both suppliers and end-users along the value chain. The demonstration case studies are to be first implemented in five EU countries (NL, ES, CY, PT, IT) where prior successful technical and social steps have already been accomplished. The broader project consortium representation will be an enabler to transferring trans-disciplinary project know-how to the partner countries while motivating and inspiring relevant innovations throughout Europe.

BL2F

funding: EU Funded H2020: H2020-LC-SC3-2018-2019-2020

status: KO

BUILDING A LOW-CARBON, CLIMATE RESILIENT FUTURE: SECURE, CLEAN AND EFFICIENT ENERGY.

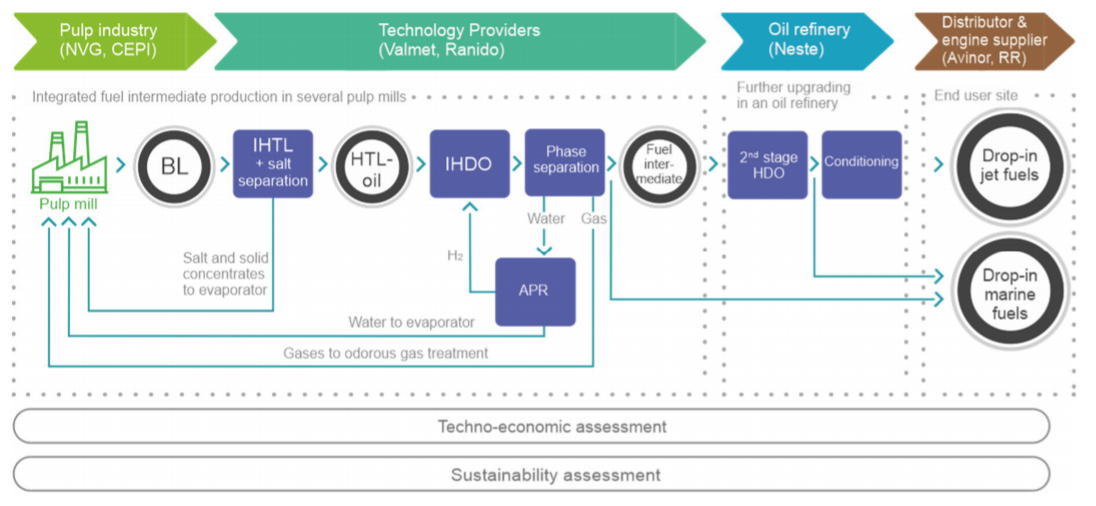

Black Liquor to Fuel (BL2F) process produces drop-in biofuels for aviation and shipping from black liquor, a side stream of

chemical pulping industry. 83 % CO2 reduction compared to fossil fuels, and competitive production cost of 0.90 €/l for dropin sustainable aviation fuel are received. A large deployment, using a variety of biomass, can yield >50 billion liters of

advanced biofuels by 2050, then satisfying the EU demand for advanced biofuels for aviation (15 Mtoe) and shipping (30

Mtoe).

First-of-a-kind Integrated Hydro Thermal Liquefaction (IHTL) process at pulp mills produces fuel intermediate for further

upgrading in oil refineries. Biomass is converted to low oxygen content (< 10 w-%) HTL-oil in water of reductive conditions at

up to 400 ˚C, 300 bar. The expected energy yield is >85 %. Integrated hydrothermal HydroDeOxygenation (IHDO) will

further upgrade HTL-oil to fuel intermediate (< 5 w-% O2), classifying as bunker-like marine fuel or feedstock for high-quality

aviation and marine fuels production.

The process innovations of BL2F are: 1) combined salt separation and HTL-reactor, enabling direct upgrading of HTL-oil, 2)

reforming of the aqueous phase to hydrogen, decreasing the need for external fossil hydrogen in IHDO, 3) integrating the

process to pulp mill, offering cost reductions in treating of the gaseous and solid side streams by existing process

installations.

The BL2F is supported by CEPI, Avinor, and Rolls Royce and covers the whole value chain: The 6th largest producer in the

world of bleached eucalyptus kraft pulp NVG, the leading biorefinery supplier Valmet, catalyst developer Ranido and Neste,

the world’s largest producer of renewable diesel collaborate with excellent research partners; VTT, PSI, SINTEF, Tampere

University, KIT, Brunel University London. LGI and industrial partners maximize the impact of the project. The ambitious

goals and strong consortium strengthens European leadership in renewable biofuels and climate protection.

Deep Purple

funding: EU Funded H2020: H2020-BBI-JTI-2018-837998

Date: 01/05/2019

status: KO

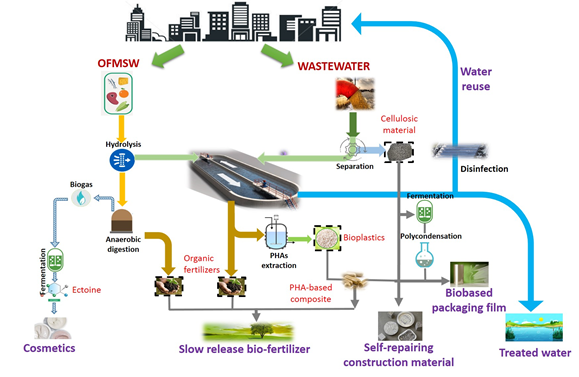

CONVERSION OF DILUTED MIXED URBAN BIO-WASTES INTO SUSTAINABLE MATERIALS AND PRODUCTS IN FLEXIBLE PURPLE PHOTOBIOREFINERIES.

DEEP PURPLE creates a holistic consortium to transform diluted urban bio-wastes, including mixed waste streams, organic fraction of municipal solid waste (OFMSW), wastewater (WW) and sewage sludge (SS), into feedstock for bio-industry to obtain sustainable bio-products. This revolutionary concept will be implemented in a novel Single-Site Multi-Platform Concept (Biomass, Cellulose and Biogas) to replace current polluting destructive practices with new value added concepts. The beneficial use of bio-waste is obtained by an innovative combination of optimized recovery technologies and novel solutions: the Purple Phototrophic Bacteria (PPB) PhotoBiorefinery. The use of PPB -the most versatile metabolism reported- ensures the adaption to fluctuating and diluted waste streams to support a stable profitable production chain. The first PPB PhotoBiorefinery in the EU (the biggest worldwide) will be validated in different environmental, economic, logistic, and social scenarios.

The concept will be implemented by end-users from four municipalities, namely Madrid (ES), Toledo (ES), Třinec (CZ) and Velká Polom (CZ) to transform bio-wastes (OFMSW: 422 t/y, mixed waste: 438,000 m3/y) into high-added value bioproducts: fine chemicals (bio-cosmetics), fertilizers, bio-packaging and self-repairing construction materials. The market uptake of DEEP PURPLE is facilitated by optimal logistics of bio-wastes conversion (reduction of landfilled OFMSW: 60%, WWTP solids recovery: 71%), and bio-products quality to favor their commercialization (440 t/y). The integration of value chains is boosted by relevant stakeholders participation and innovative business models, minimizing waste and maximizing benefits (85 M€ benefits, GHG emissions savings: 11,300 tCO2eq/y in 2025). Key communities (social engagement strategies) will participate in the new value creation, calibrating the returns of the project like social innovation promotion and creation of new opportunities along the urban value cycle.

Demonstration of water loops with innovative regenerative business models for the Mediterranean region (HYDROUSA)

H2020-EU (3.5.2.2-4):776643

Date: 01/09/2018

status: Commenced

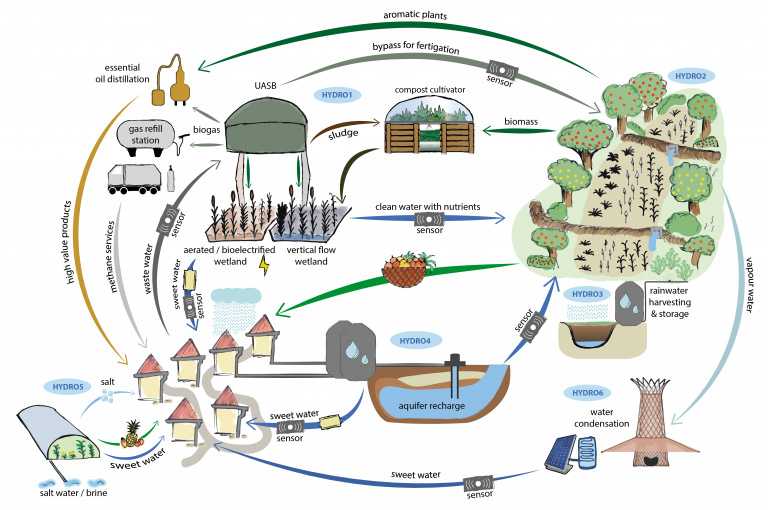

HYDROUSA will provide innovative, regenerative and circular solutions for:

(1) nature-based water management of Mediterranean coastal areas, closing water loops.

(2) nutrient management, boosting the agricultural and energy profile.

(3) local economies, based on circular value chains.

The services provided lead to a win-win-win situation for the economy, environment and community within the water-energy-food-employment nexus.

HYDROUSA water loops will include water from non-conventional sources including wastewater, rainwater, seawater, groundwater and vapour water, all resulting in recovered and marketable products. HYDROUSA will demonstrate at large scale the feasibility and sustainability of innovative, low-cost water treatment technologies to recover freshwater, nutrients and energy from wastewater, salt and freshwater from seawater, and freshwater from atmospheric water vapour. Water conservation solutions including aquifer storage and sustainable agricultural practices including fertigation will be applied. The solutions will be demonstrated on 3 major touristic islands in Greece. Detailed technical and financial deployment plans will be established for replication in additional 25 locations worldwide. Through the on-site water loops of HYDROUSA, complex supply chains for resource recovery are not required, as producers are directly involved as consumers of derived products. HYDROUSA will combine traditional skilled workmanship with modern ICT integration in beautiful and smart automation systems. HYDROUSA will revolutionise water value chains in Mediterranean areas and beyond, from water abstraction to sewage treatment and reuse. The proposed HYDROUSA solutions show massive potential to change the way humans interact with water, food and energy.

Circular Economy System for Multi-Source Biomass conversion to Added value Products (Circ4Bio)

Funding:EU Funded

status: Commenced

The overall aim of the Circ4Bio project is to achieve high GHG emission savings from the substitution of fossil fuels with advanced biofuels, as well as to promote the implementation of a circular economy concept for biomass. The project will (i) demonstrate an innovative biorefinery concept for the production of bioethanol, using bioproducts from biomass produced from household, catering and industrial food waste, and from agricultural residues, and (ii) create an interactive platform for facilitating the circular economy concept for 2nd generation biomass. Specific objectives are to:

(1) Improve the knowledge base for the proposed biorefinery concept.

(2) Operate, test and optimise the biorefinery system to minimise energy and raw material consumption, maximise yield and achieve energy autonomy.

(3) Achieve high quality ethanol from used oil and digestate.

(4) Achieve high performance of fuel ethanol mixes in motor engines.

(5) Boost biogas production with the removal of volatile fatty acids and to investigate the potential for their conversion to bioplastics.

(6) Demonstrate the sustainability and the economic viability of the proposed system, and to define its business requirements.

(7) Map the available biomass to define the optimal supply chain.

(8) Promote public awareness on climate change mitigation, circular economy concepts and on 2nd generation ethanol, and to promote the acceptance of biobased products from waste and residues.

(9) Develop a transfer and replication strategy for the target regions.

(10) Mobilise wide market uptake and replication of the project solutions.

(11) Foster jobs and increase capacity building in relevant technologies for increased competitiveness.

Ad-Bio

funding: EU Funded

Date: October 2020

status: Commenced

Advanced biological wastewater treatment processes (Ad-Bio).

The aim of this research is to strengthen research excellence in Turkey on advanced biological wastewater treatment processes for energy and materials recovery and for nutrient removal from wastewater. The shift from energy intensive wastewater treatment processes to low carbon footprint processes which can achieve significant resource recovery is considered to be the way forward for the wastewater treatment plants of the future. Brunel University is already implementing advanced processes, which include short-cut nitrogen removal, membrane bioreactors (MBRs) and upflow anaerobic sludge blanket coupled with suitable post treatment in order to treat municipal and industrial effluents. This research knowledge will be transmitted to the Ataturk University which is currently working on biological processes for wastewater treatment, including MBRs. An anaerobic MBR will be developed and operated in Brunel in order to treat dairy wastewater. The reactor will recover energy from wastewater and will be used to train students and to promote research collaboration between Ataturk University and Brunel University.

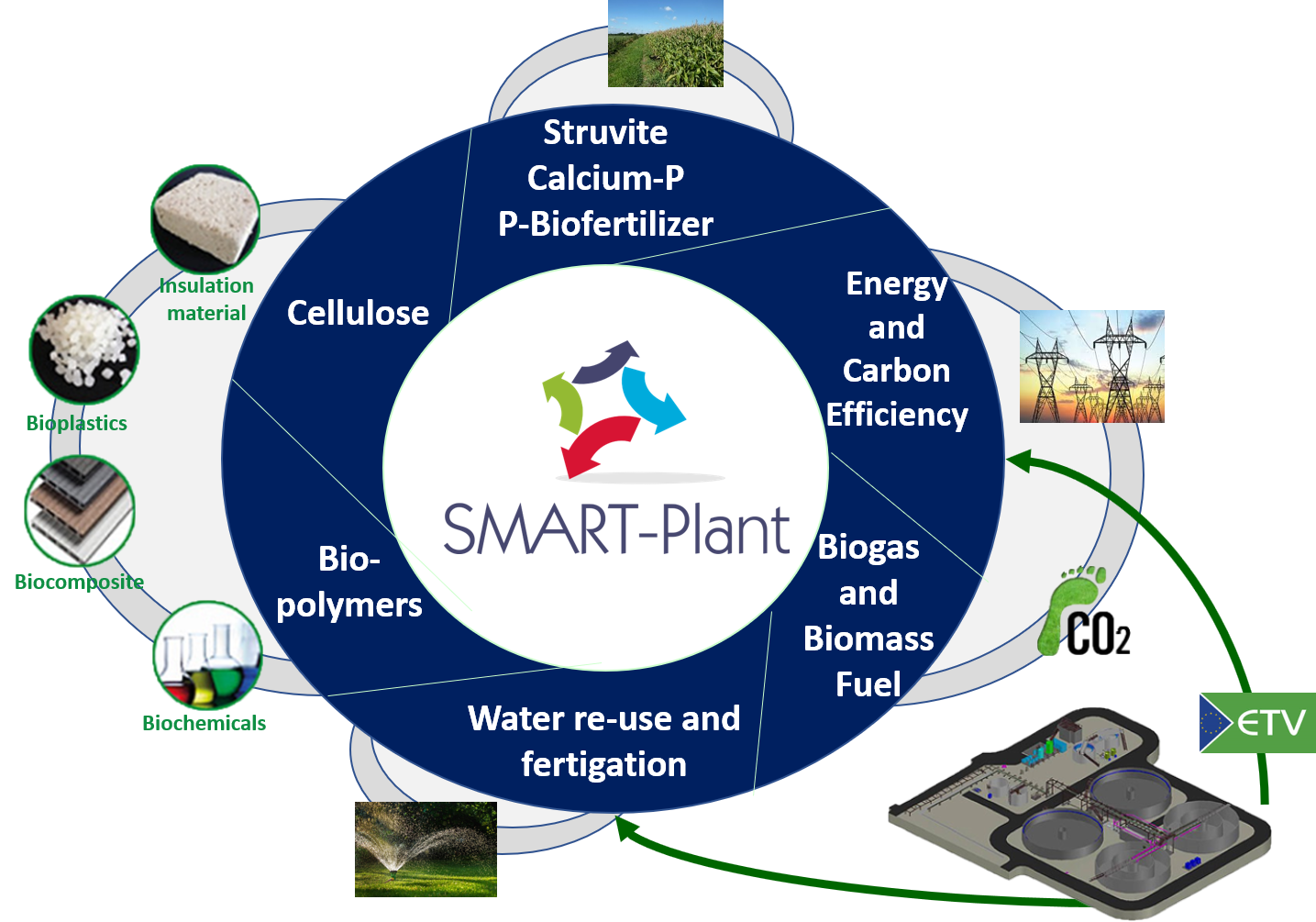

SMART-Plant

funding: EU Funded: H2020-EU.3.5.4.

Date: May 2020

status: Finalised

Scale-up of low-carbon footprint material recovery techniques in existing wastewater treatment plants.

SMART-Plant will scale-up in real environment eco-innovative and energy-efficient solutions to renovate existing wastewater treatment plants and close the circular value chain by applying low-carbon techniques to recover materials that are otherwise lost. 7+2 pilot systems will be optimized fore > 2 years in real environment in 5 municipal water treatment plants, inclunding also 2 post-processing facilities. The systems will be authomatisedwith the aim of optimizing wastewater treatment, resource recovery, energy-efficiency and reduction of greenhouse emissions. A comprehensive SMART portfolio comprising biopolymers, cellulose, fertilizersand intermediates will be recoveredand processed up to the final commercializable end-products. The integration of resource recovery assets to system-wide asset management programs will be evaluated in each site following the resource recovery paradigm for the wastewater treatment plant of the future, enabled through SMART-Plant solutions. The project will prove the feasibility of circular management of urban wastewater and environmental sustainability of the systems, to be demonstrated through Life Cycle Assessment and Life Cycle Costing approaches to prove the global benefit of the scaled-up water solutions. Dynamic modeling and superstructure framework for decision support will be developed and validated to identify the optimum SMART-Plant system integration options for recovered resources and technologies.Global market deployment will be achieved as right fit solution for water utilities and relevant industrial stakeholders, considering the strategic implications of the resource recovery paradigm in case of both public and private water management. New public-private partnership models will be explored connecting the water sector to the chemical industry and its downstream segments such asthe contruction and agricultural sector, thus generating new opportunities for funding, as well as potential public-private competition.

CFoot-Control

funding: EU Funded

Date: 2014 - 2018

status: Finalised

C-FOOT-CTRL aims to develop, test and validate a new software tool for the onlinemonitoring, control and mitigation of the carbon footprint of wastewater treatment plants (WWTPs). Gaseous emissions are emitted from various stages oftreatment in a WWTP.

Currently, in developed countries the energy required for wastewater treatment accounts for approximately 3% of the total electrical load. Also, WWTPs are the biggest single energy consumers of municipalities with a share of 20% of the total energy consumption. The typical energy efficiency of WWTPs in Europe is less than 50%, when energy efficiency is defined as the ratio of electricity generated at WWTP to the electricity needed from grid to operate the WWTP. Strategies to decrease the required amount of energy may in fact cause greater harm due to the increase of GHG emissions. Various greenhouse gas emissions are associated with the construction and operation of WWTPs. These include carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O), with nitrous oxide being 298 times more harmful than CO2.

The development of a tool that will be able to accurately record on line the various gaseous emissions of WWTPs is important in order to (i) track the emissions at the moment of occurrence (ii) immediately apply measures to reduce gaseous contaminants and to (iii) link the gaseous emission with a particular activity in the plant. The on line GHG emissions monitoring and control system will be an innovative, low cost and flexible system based on sensor networks for monitoring and ‘supervising’ activities aiming to reduce GHG emissions during the operation of WWTP.

Determination of the most effective & low-cost solution for tackling the problem of galvanized iron corrosion in specific parts of the Affinity Water piping network, which is caused by the surface water imported from Grafham reservoir (consultancy)

Date: October 2018 - Dec 2021

status: Commenced

Contact us for more detail

Towards Carbon neutral and Cost-efficient Sewage Treatment (consultancy) (CO2ST)

Date: 2019 - 2021

status: Commenced

Contact us for more detail

Circular Shop Window (consultancy)

Date: 2019 - 2021

status: Commenced

Contact us for more detail

MBR design and start-up (consultancy)

Date: May 2020

status: Finalised

Contact us for more detail

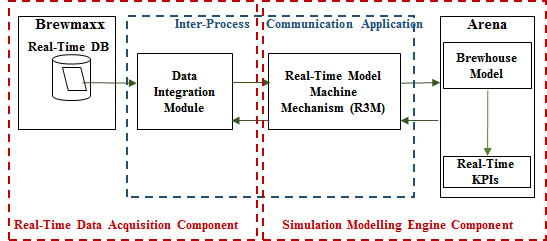

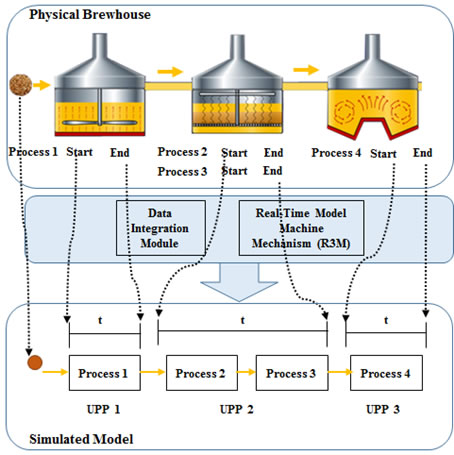

Automatic Real-Time Translation of Plant Data into Management Performance Metrics: A Case for Real-Time and Predictive Production Control - Brewery Technology.

Date: 01/10/2015

status: finalised

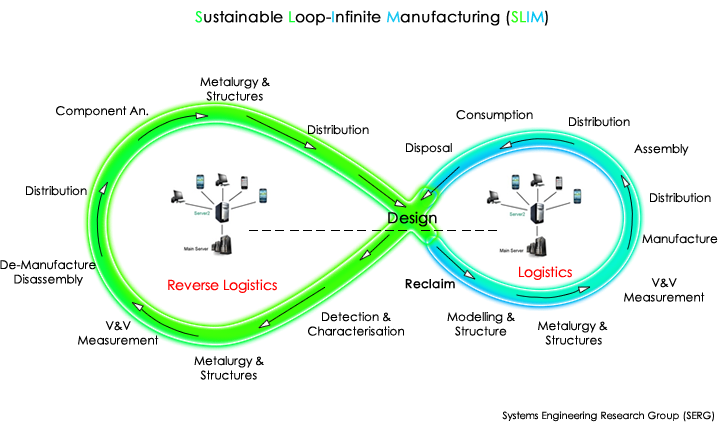

The Sustainable Loop-Infinite Manufacturing Initiative.

Date: 15/06/2015

status: Foundation

1. Design philosophy for sustainable, traceable, reconfigurable, and re-manufactureble products.

2. Machine tools and techniques for automated detection, tracking and tracing, automatic disassembly, and production processes that are capable of exchanging the necessary data and knowledge vertically

and horizontally throughout the supply chain (considering the full life cycle, in our case indefinite life cycle of products and service).

3. Use of advance materials technologies for design and development of highly recyclable and reconfigurable components and devices – to retain the energy and materials within the lifecycle of products, composites and material. No Loss Philosophy.

4. Create a robust and encompassing information architecture to ensure maximum traceability, security, mobility that facilitates implementation of complex optimisation techniques to maximise efficiency and minimise waste.

5. A virtual interactive environment in which customers, industrialists, researchers, and education sector can follow this infinite loop. To discuss, understand, influence and adopt.

Further information and expression of interest click here.

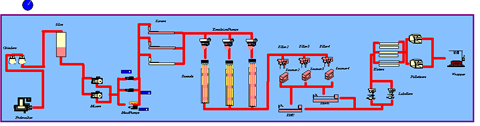

Discrete Event Simulation for one of Europe's largest Pet Food Manufacturers - Nestle' Friskies

Date: 2000

status: Finalised

A full system simulation and data analysis and report on the findings. The objectives of the project were:

1. Data collection and analysis.

2. Model development based on information collected and simulation objectives.

3. Analysis of results consisting of resource utilisation, average throughput time, and system output. Highlighting anomalies and bottlenecks in the system.

4. Proposals for system improvement and investment strategy.

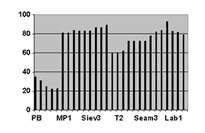

Systems capability (SC) evaluation

Date: 09/1999-12/1999

status: Finalised

o date SC has generally been assessed and analysed based on subjective assumptions. Qualitative attributes such as: reputation, collaborations,

knowledge, success in delivering final products, and technical ability coupled with some quantitative attributes i.e. size of the company, capital,

and other measurable attributes play important role in this assessment. Non-standard linguistic characteristics attributed to systems by systems' analysts

have left key decision makers exposed to misjudgments with devastating consequences.

Especially these over estimations have been displayed in the latest crashes in IT and Telecommunication industries.

Hence a platform of some sort for standardisation of the evaluation technique is required. Constituent elements of evaluation and the mathematical

model to quantify the qualitative and linguistic characteristics of systems capability seem to be necessary.

We developed a mathematical model to depict and compare the capability of companies that are active in a specific

high-tech industry to aid the decision makers in their pursue to overtake and merge with rival companies.

The models developed for this project are currently being expanded and developed.

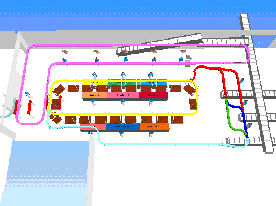

MEATRAC - Automated Tracking and Handling of meat cuts (AFM 110) DEFRA project no. CSA 5261.

funding: Department of Environment, Farming, and Rural Affairs (DEFRA) Advanced and Hygienic Food Manufacturing LINK programme.

Date: 11/1999-5/2002

status: Finalised

This project was sponsored and funded by Department of Environment, Farming, and Rural Affairs (DEFRA) Advanced and Hygienic Food Manufacturing LINK programme. The consortium of partners that delivered the project comprised of, Brunel

University, Pera, Dawn Meats, Safeway Stores, Scootabout International, Rockwell Automation, Codeway, Arca Systems, Street CraneXpress, Rehau, and Avery Dennisson.

The main challenges tackled in this project were:

1. Design of an intelligent material-handling system (bead-driven conveyor system) that stores and transfers the information of a given piece of meat along its path. This overhead conveyor is capable of diverting the pieces of meat from one path to another with minimal effort. It is designed to ensure optimal ergonomics.

2. Standardisation and automation of production process, enhanced tracking and labeling techniques, and compatible control systems are the main elements that assisted the system designer in solving complexities of carcass disassembly.

3. Non-invasive sate-of-the-art Radio Frequency Identification of products within the shopfloor to ensure 100% traceability.

4. Design and development of a control system capable of retrieving, storing and transferring information along the route in a local area network. And also complex routing of material along the plant.

5. Development of a standardised database system to store and disseminate information. Also included is a user-friendly software interface for information retrieval and reporting.

This system is currently being developed for commercial plants.

Resource Management and Product Traceability Decision Tool( e-Track) - BridgeLink Feasibility Study

funding: Department of Environment, Food and Rural Affairs (AFM218br)

Date: 01/06/2004

status: Finalised

his PROJECT investigates the feasibility of a quick-response decision modeller to help managers deal with the demands of volatile food production environment.

It argues the need for a focused, real-time, high quality information apparatus to support production managers on the shopfloor.

This is achieved by providing specified definitions for the key performance factors (KPF) within the industry. A cost/benefit analysis tool will be presented that reports on system performance.

The aim of the proposed system is to improve the quality of decisions made during food production process with the aim to realise the real operational costs thus improve profit margins. By creating the proper information environment and equipping the system with suitable prediction platform stressed managers can be advised on various action plans and the consequences for each decision. This is to be achieved by firstly, creating a comprehensive information environment for precise measurement of the state of the system in real-time. Secondly, provide an accurate prediction platform for improved decision-making.

Our research to date reveals that there is no quick response decision- making tool in the industry that helps production managers to evaluate the gains and losses behind each option available to them.

The problem of Harmonic Filter Burns in Coal Power Plants (JEV Malaysia).

Date: 02/05/2015

status: Commenced

Contact us for more detail